The key to excellence

Value-for-money 3D printing materials

NORTHBRIDGE NEW MATERIAL TECHNOLOGY (SUZHOU) CO., LTD. (hereinafter referred to as KEXCELLED) was established in November 2013 and is located in the B2 building of Chaoyang Industrial Park, Caohu Industrial Park, Suzhou Xiangcheng Suzhou. It is a leading international supplier of additive manufacturing materials, focusing on the development, production, and sales of additive manufacturing polymer materials.

Since its establishment, the company has been awarded as a private technology enterprise in Jiangsu Province and a national high-tech enterprise and has applied for a total of 39 patents. We have established extensive and in-depth cooperation with famous enterprises and institutions at home and abroad, such as LEHVOSS, DOW, HUNTSMAN, COVESTRO, and the Intermediate Center of the Chinese Academy of Sciences. And in 2016, we established a European branch to start the process of global development. The company is close to the users in many aspects, such as product concept, product development, and business process, and the users are the starting and ending point of all our work.

Our Products

KEXCELLED has a rich and high-quality product range in FDM materials and has successfully independently developed high-quality modified basic materials such as Transparent PLA, High-toughness PLA, Flame-retardant PLA, and PLA/CF composite materials, low-odor ABS, and PETG materials. We also innovatively introduced the concept of aesthetic materials into 3D printing and developed a variety of aesthetic materials suitable for 3D printing, such as silk effect, marble effect, matte effect, spray-free metallic effect, sparkling effect, and wood effect. For extremely demanding industrial applications, we have developed a variety of high-performance engineering materials such as PC materials, PEI materials, modified PA and its fiber composite materials, low warpage PEEK, high-level interlayer adhesion PEEK, and its fiber composite materials.

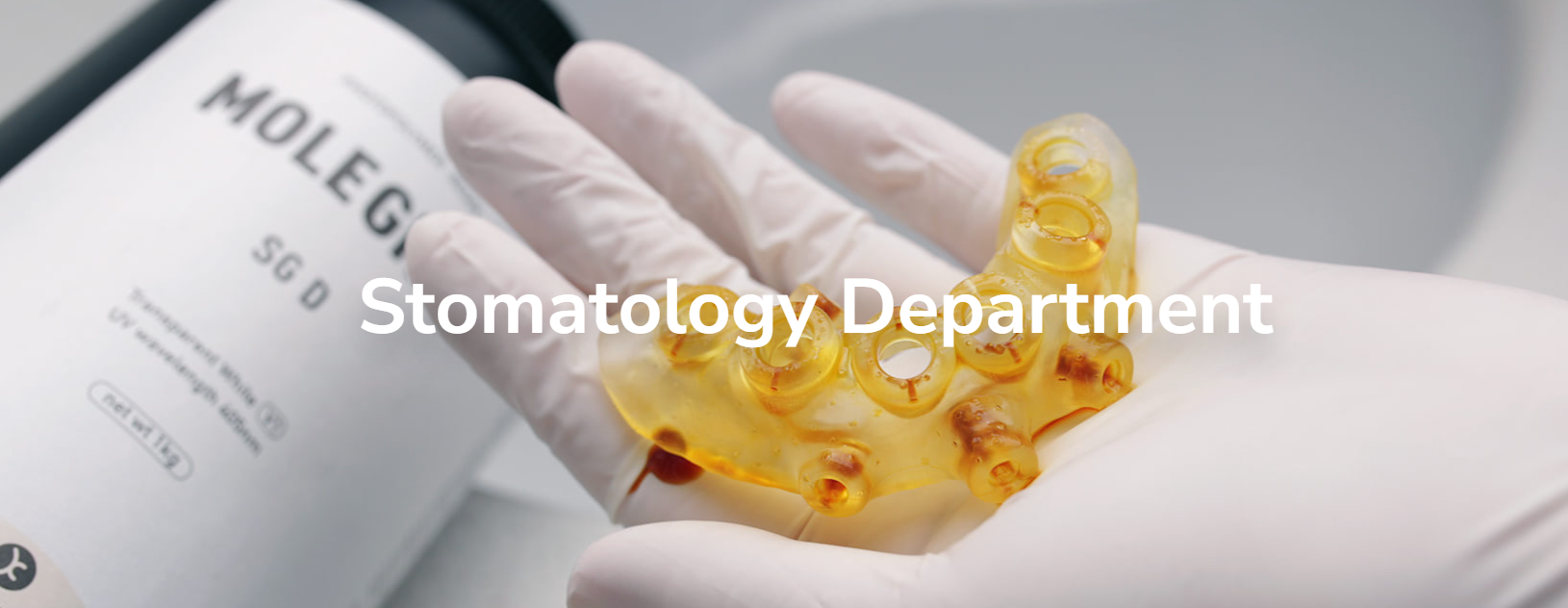

In terms of photocuring 3D printing materials, we have made in-depth development of materials for DLP and LCD. At present, we have formed 4 application categories such as Prototyping, Functional, Dental, and Jewellery, and two major product series, DLP, and LCD, with a total of 28 materials. It can be widely used in models, figures, dentistry, jewelry casting, fixtures, footwear, and other fields. All related products have obtained corresponding certifications, such as DIN degradable certification, flame retardant certification, medical device filing, biocompatibility certification, etc.

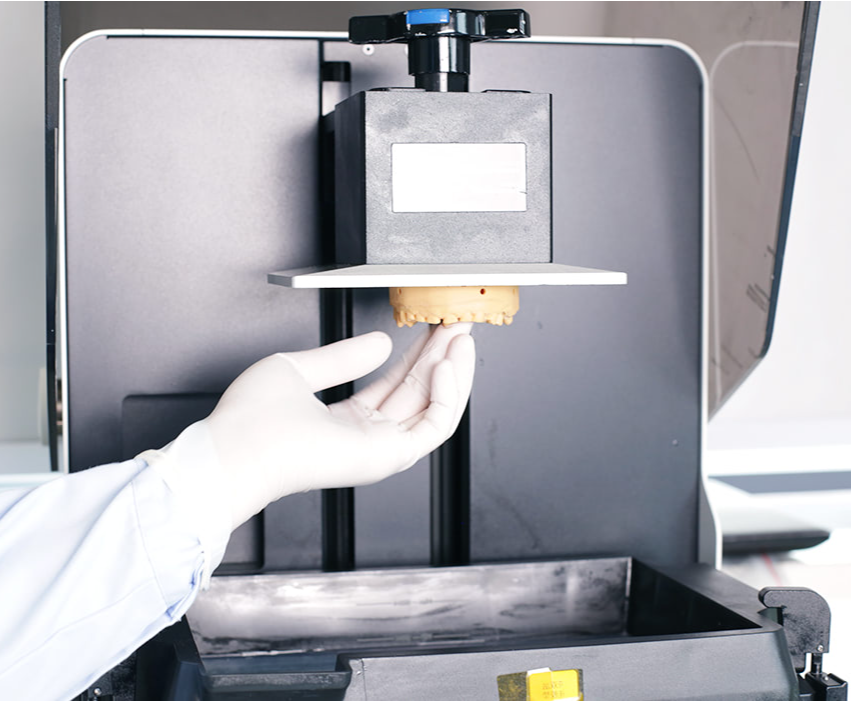

In recent years, more and more medical institutions have started to use 3D printing technology to realize rapid manufacturing of medical models to help medical treatment and patients communicate, diagnose and formulate surgical plans.

Oral digitalization is the inevitable development trend of the global oral medicine industry, and 3D printing, as an indispensable part of it, has been paid more and more attention by oral practitioners, and its popularity is increasing year by year.

3D printing technology meets the requirements of the oral industry for precision, complexity and customization. High precision and high accuracy can reproduce complex tooth structures 1:1, making diagnosis more accurate;

Compared with the traditional processing method of dental medical products, 3D printing technology greatly simplifies the production process, significantly speeds up the dental treatment process, and greatly reduces the waiting time of patients at the chair.

Digital Dentistry

3D Printing

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Japan / 日本

Japan / 日本

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/file-7.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/Our-commitment-to-digital-dentistry-is-a-cornerstone-of-our-strategy.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/Shutterstock_1051488260.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/file-8.jpg)

:sharpen(level=0):output(format=jpeg)/up/dt/2024/07/Fruit-leathers-chewing-gums-help-reduce-errors-of-panoramic-imaging.jpg)

:sharpen(level=0):output(format=png)/up/dt/2023/06/Align_logo.png)

:sharpen(level=0):output(format=png)/up/dt/2023/07/DirectaDentalGroup_Logo_2023_03_2lines_lowres.png)

:sharpen(level=0):output(format=png)/up/dt/2024/06/UnionTech-Logo-Hub.png)

:sharpen(level=0):output(format=png)/up/dt/2013/01/Amann-Girrbach_Logo_SZ_RGB_neg.png)

:sharpen(level=0):output(format=png)/up/dt/2013/04/Dentsply-Sirona.png)

:sharpen(level=0):output(format=png)/up/dt/2024/07/kexcelled3d-logo-black.png)

:sharpen(level=0):output(format=jpeg)/wp-content/themes/dt/images/3dprinting-banner.jpg)

:sharpen(level=0):output(format=jpeg)/wp-content/themes/dt/images/aligners-banner.jpg)

:sharpen(level=0):output(format=jpeg)/wp-content/themes/dt/images/covid-banner.jpg)

:sharpen(level=0):output(format=jpeg)/wp-content/themes/dt/images/roots-banner-2024.jpg)